News

-

Revolutionise Your Fleet with our Efficient ePTO System

Date: 29-05-2025Cut Costs, Boost Efficiency and Reduce Your Fleet’s Environmental Impact with the Efficient ePTO System -

Get a head start on building that Log Splitter

Date: 01-04-2025With winter on the way... How about log splitter kits to help you keep the fire going. -

Beat the Heat - Use Emmegi Hydraulic Oil Coolers

Date: 03-03-2025Monitoring oil temperatures is imperative when the system is in operation. If the oil temperature rises above a reasonable working temperature when operating, the odds of system breakdown will increase significantly. -

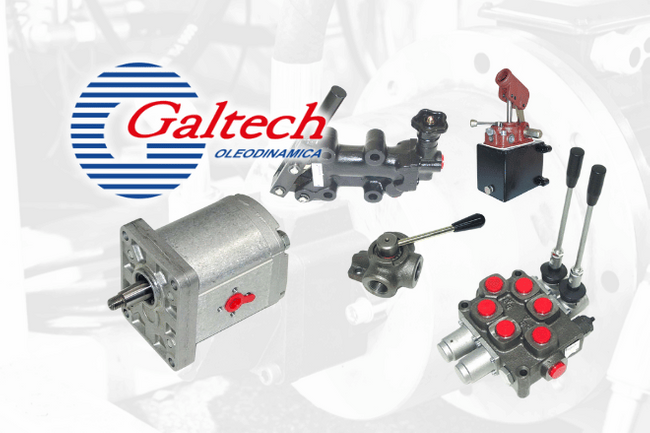

Galtech Hydraulic Products

Date: 03-03-2025Hyspecs stocks a full line of Galtech hydraulic hand and gear pumps, motors, mono-block control valves and diverter valves. -

Excavator Hose Burst Safety Valves

Date: 02-03-2025Don’t Drop Your Load If Your Hose Bursts! Hyspecs SAFEX valves are designed to be mounted directly to the boom and/or the stick (arm) cylinders of hydraulic excavators. -

Smart Reservoir - Variable Volume Reservoir (VVR)

Date: 20-01-2025Hyspecs can offer you an alternative to bulky oil tanks and using large quantities of hydraulic oil. -

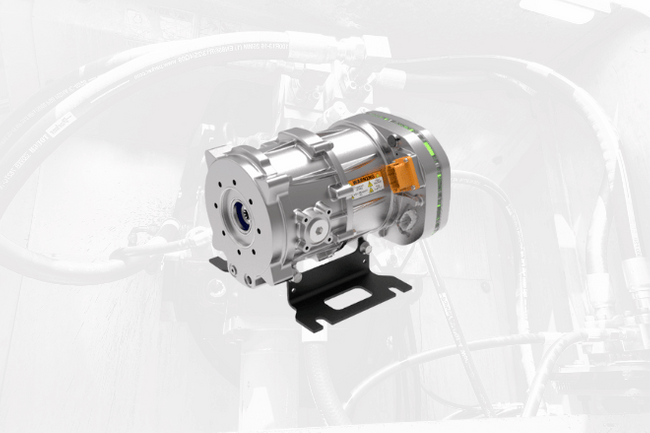

Hydrapulse ® EHPU

Date: 18-11-2024The Hydrapulse® EHPU is specifically designed around increasing efficiency in hydraulic applications, and simplifying the transition to EV and Hybrid platforms. -

Hyspecs Electrical

Date: 16-10-2024At Hyspecs we don't just do Hydraulics. We also have a team of electrical and automation engineers ready to assist your next project. -

DANFOSS ePanda ePowerpack

Date: 16-10-2024The ePowerpack is part of Danfoss ePanda series, the new Low Voltage portfolio for electrification. -

Read more about the Hydraulic Dock Leveller Power Packs

Date: 05-08-2024Need to service or replace your Dock Leveller hydraulics? Hyspecs has you covered. -

HydraForce & Bucher, Brands You Can Trust

Date: 05-08-2024Hydraforce and Bucher (Command Controls) are well known brands in the Hydraulic industry and Hyspecs can supply you with a range of their products. -

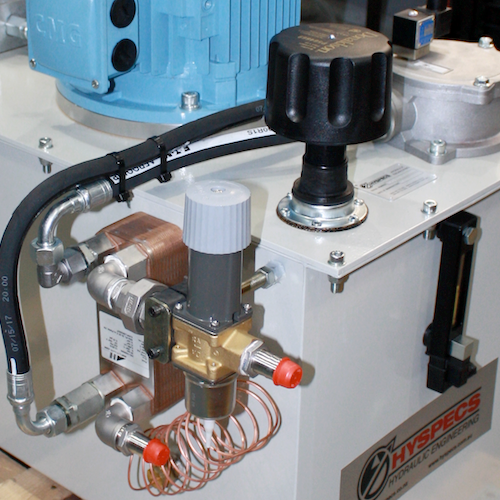

Hyspecs Hydraulic Power Packs

Date: 13-05-2024Looking to buy new or replace an old hydraulic power pack? At Hyspecs we manufacture and stock a wide range of hydraulic power packs. -

HYSPECS Brisbane is on the Move

Date: 27-03-2024Please note that HYSPECS Brisbane (Hydraulic Specialties Pty Ltd) will be moving to a new location on the 25th of March 2024. -

Hydraulic Manifolds & Cartridges

Date: 11-03-2024Get rid of multiple discrete hydraulic valves and hoses, and replace with a fully integrated hydraulic cartridge valve manifold. -

Poclain Hydraulics

Date: 12-12-2023Hyspecs are the go to providers for Poclain Hydraulics in AU and NZ. -

miniBOOSTER range of pressure intensifiers

Date: 20-11-2023miniBOOSTER is commonly used to supply high pressure to attachments where small cylinders and high force are required. -

Wirelessly Monitor & Data-Log Pressure & Temperature

Date: 08-05-2023Take advantage of remote pressure transducer monitoring using your smartphone or tablet. -

Sakai Rollers Adapted for the Poclain MK09 Motor

Date: 27-03-2023Any Sakai Rollers fitted with Poclain MK08 motors that are now obsolete, can be upgraded to take the Poclain MK09 motor. -

Hyspecs Electrical Capabilities and Projects

Date: 31-10-2022In order to meet your electronic and automation requirements and to provide the right solution every time, Hyspecs has a team of engineers that work with the sales and projects departments. -

Hyspecs Turns 50!

Date: 15-06-2022This is a massive milestone for any business. Â We are especially proud to be able to say that there are customers that were with us from the beginning, still trading with us today. -

Walvoil 6-Port Electric Diverter Valves

Date: 03-04-2022Need to add another hydraulic function to your machine? -

The Turntable That Costs as Much as a House

Date: 17-02-2022At Hyspecs, you never know what sort of project will turn up on the doorstep. -

Turnkey Hydraulic Systems

Date: 27-10-2020Looking for a complete hydraulic system? With expert design and build engineers, you can trust Hyspecs to get the job done, from go to whoa. -

Webtec Hydraulic Testing Equipment

Date: 27-10-2020Do you want to quickly diagnose, repair and certify a hydraulic system is working correctly again?